Embedded360 is one of the leading electronic manufacturing Services company with specialization in quick turnaround of Prototypes and low to medium scale production.

Embedded360 caters to all OEM & ODM enterprises requiring electronic contract manufacturing services(EMS) from PCB fabrication, sourcing of components, and complete electronic PCB assembly. We have a state of the art PCB manufacturing facility, a dedicated highly skilled professional team for procurement of high-quality low-cost electronic components, and a PCB assembly team to meet the requirements of our OEM & ODM customers.

Our Printed Circuit Board (PCB) Manufacturing and Assembly Services

Embedded360 is a full-service PCB assembly company, so you have our team available throughout the conceptualization stage and to a successful product launch. Our priority is delivering a high standard of work with quick turnaround times in everything we do for you. Our world-class equipment and skilled engineers perform a multitude of electronic manufacturing services, completing short-run productions of up to 50,000 units at a time.

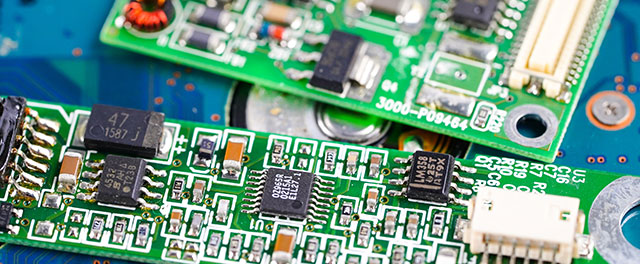

Surface-Mount Technology (SMT)

Mounting electronic components to the surface of a printed circuit board allows for more compact and space-saving configurations. For high-volume projects, we offer a significant degree of automation in surface-mounted PCB assembly, including component placement, soldering and inspection. We can assist with producing complex dual-sided circuit boards that serve specialized applications in critical situations.

Thru-Hole Manufacturing

The thru-hole process involves drilling openings into a PCB and inserting component leads for soldering. The high-strength and durability of these bonds make thru-hole designs a reliable choice in harsh, demanding environments. While it’s an older method than SMT, we know thru-hole is far from obsolete and continues to thrive in the military and aerospace electronics that we service. Embedded360 is capable of fully or partially automated through-hole PCB assembly to boost efficiency and overall quality.

Testing and Inspection

Embedded360 offers rigorous PCB testing and examinations of completed units to ensure they perform to your expectations, and most importantly, for the demands of your customers. We do extensive functional testing to verify proper routing and soldering, and every finished unit is checked by automatic optical inspection equipment to identify component-level defects. Our personnel can utilize our X-ray inspection station to scope for potential issues within the circuit board layers.

Contract Manufacturing

Embedded360 is a modern-day leader in contract manufacturing services. While outsourcing your printed circuit board assembly is a significant decision, we’re poised to be a capable and dynamic force operating on your side. We’ll assist with PCB designs and layout, and our array of machinery can streamline assembly to prepare your unit for shipping more quickly. Partner with us, and you’ll have an engaged and experienced workforce striving to meet your every goal with production

Electronic PCB Assembly

Embedded360 leads the way in offering comprehensive service and support throughout the product development stages. Our skilled assembly specialists are available for consulting to determine which PCB fabrication method could be best for your application. We’ll help manage the prototyping and move toward scaling up production on a finalized design. At every step, we focus on transparency and flexibility to meet your demands for a satisfactory result.

Box Builds/Turnkey Assembly

We provide turnkey solutions with completing and delivering your product, including system and sub-level assembling in-house. Whether we’re installing wire harnesses, loading software or configuring settings, Embedded360 can work with customized enclosures and packaging to enhance preparation for the market. After box building is complete, we can either return the product to you or drop-ship directly to your customers to free up your company’s resources.