Today’s market mantra is to create better and efficient products and to reduce time to market by enhancing productivity and security which most companies are struggling to meet. Embedded360 creates a difference by arriving at product realization solution after fully comprehending your business challenges and ideas through a collaborative approach.

Our services include transforming legacy industrial systems, performing tear-down analysis, and ensuring complete knowledge management for old products.

Embedded360‘s extensive experience in designing industrial systems for equipment manufacturers and its ‘best fit’ combination of domain and technology expertise has resulted in several successful product realizations.

Embedded360’s services cover the whole gamut of Industrial Design and Product Development lifecycle in the Industrial systems domain.

Key Achievements

- Over 10+ rich experience across automotive industry

- 120+ Scenarios Configured and tested

- 500+ Man years of manufacturing experience

- 60+ Industrial Projects

- Ability to take on new technology challenges with minimized risk

- Build a strong product portfolio at the right time to market

- Enable seamless integration of products and systems with third-party systems

- Capability to migrate to different platforms

- Optimum combination of IPs and engineering services to build a complete solution

Visibility

- Turn information into actionable insights

- Greater control, visibility over supply and volatile demand

- Access and visibility throughout the manufacturing value

Response Time

- Accelerate production cycles

- Reduce response times to improve customer satisfaction

- Deliver right products and the right

Collaboration

- Enable communication flow across the board

- Co-innovate with customers during product development

- Collaborate with geographically dispersed work teams

Control

- Greater control over product quality failures

- Provide service excellence predictability

- Ensure reliable performance across global networks

- Lowering deployment costs and operational down-times

- Automated solutions to enhance equipment performance

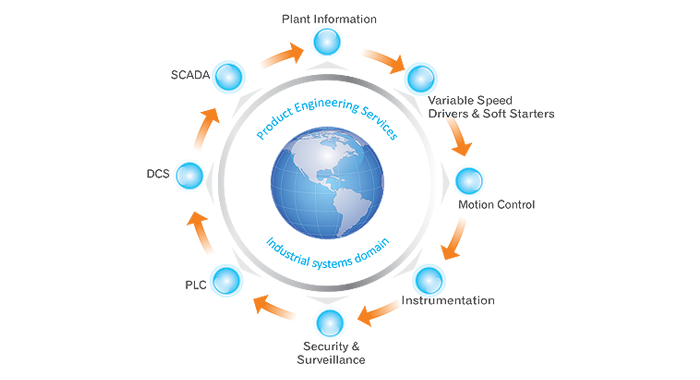

Our skills across industrial automation products such as DCS, PLC, Field Instruments, SCADA, MES and EMI can be grouped into three areas:

- Legacy Products – Re-engineering, porting, migration, value engineering and support.

- Active Products – Sustenance, EOL support, engineering change request management, localization, feature enhancements, green compliance, bug fixing, technical support and documentation.

- New Product Development – Conceptualization, architectural and detailed design, hardware, application software, user interface design, firmware, mechanical design and development, prototyping, hardware-software integration, testing and V&V, manufacturing support and documentation.